Instruments

Product Categories

Resources

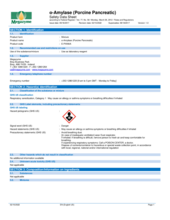

To get this fault, the temperature sensor in one or more of the paddle heaters is reporting high temperatures. This could occur at different times under specific conditions such as: During the Amylase phase or when the instrument is idle if a...

Static electricity during the weighting process: The largest contributor to poor results is the effect of static electricity on the weighing process. Because plastic gloves can contribute to static electricity, only use anti-static gloves. To...

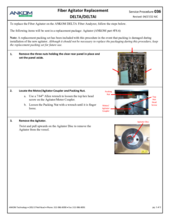

Possible Causes: (1) The packing nut may be too tight. For proper tightening instructions, refer to Service Procedure Agitator Packing Maintenance and Nut Adjustment (AS001). (2) The packing assembly may have corrosive buildup. If periodic...

Refer to the Fat Extraction Process section of the ANKOM XT10 Extractor Operator's Manual. See subsection, Sample Preparation Procedure for Crude Fat.

Yes. For instructions on how to extract liquid samples, view ANKOM XT10 & XT15 Crude (Free) Fat Extraction of Liquid Samples and refer to the Sample Preparation section of the Operator’s Manual.

Yes, all samples should be treated the same during the drying process. The biggest and most common cause of artificially high crude fat results is incomplete drying in the pre-extraction phase. Because our technique uses the indirect method of...

When the lid is raised, some residual acid may flow onto the hinges and the handle. Over time, corrosion will occur if this happens. When lifting the lid after a run, it is recommended that the lid be wiped off with a paper towel to prevent dripping...

If a Mojonnier solvent (pet ether, ethyl ether, ethanol) is utilized, a blank value of 0.0030g is normal. If pet ether or hexanes are used, a blank value of 0.0010g is normal. During the hydrolysis phase, fat migration may occur with samples that...

IDF filter bags have a shorter length of clear polypropylene material and a taller filter at the bottom of the bag. SDF filter bags have a longer length of clear polypropylene material and a shorter, wider filter at the bottom of the bag.

Use alcohol on both the underside of the modules and the bottles. Do NOT use an autoclave as the electronics and bottle coating will be damaged.

Bag breakage can occur when the heat sealer setting is not hot enough to ensure a good seal. Make sure each bag is sealed within 4mm of its open end. This section includes a narrow polypropylene strip that provides elasticity to the heat-sealed area...

Crude Fat results could be low for any of the following reasons: The extraction was not run long enough. The sample was not post-extraction dried enough. Fat migrated from a bag during the pre-dry step. Desiccant was either not used or incorrectly...

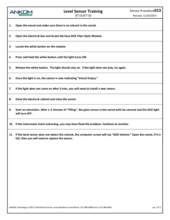

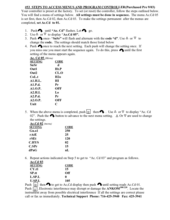

To update your GPM software: 1) Purchase the GPM software appropriate for your system. GEN2 systems (serial #’s <900) require GPM software version 11.4 ( Part #: RF3 ) GEN3 systems (serial #’s >1000) require GPM software version 15.0 ( Part #: RF3X )...

This fault occurs when the temperature sensor in the in-line heater reports a temperature exceeding 135˚C. The E4 error message on the touch screen display will indicate the temperature at the time of the fault. When this fault occurs the instrument...

This fault occurs when the temperature sensor reports a high temperature while the in-line heater is attempting to cool within the required timeframe. Cooling is facilitated by flushing water through the lines of the in-line heater. The first time...

Maintenance procedures can be found under the section titled, "Periodic Maintenance" in your TDF Operator's Manual and the TDF Preventative Maintenance Process Guide (TS047). A maintenance checklist can also be found below.

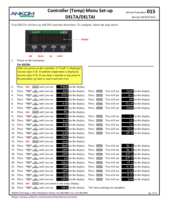

Possible cause: A power surge has occurred. Solution: Reprogram your controller using the controller menu setup in your Operator's Manual

Possible Causes: 1) Sample size is too large. 2) Bags were not acetone rinsed. 3) The rubber baffle spacers fell off. Possible Solutions: 1) Ensure that the procedure is followed completely. 2) Reduce sample size to .025 per procedure. 3) Rinse bags...

An E12 fault is the result of the high-pressure sensors reading input pressure above 100 psi. N2 Input pressure is always monitored, and the fault could occur at any point during a run. The fault will interrupt the run and wait for the operator to...

The ANKOM FLEX Total Fat analysis run time is just under two and a half hours. Technician time is only five to ten minutes of set-up prior to running the instrument. This includes weighing samples into each digestion vessel and loading the digestion...

The FLEX method saponifies at 75°C for forty-five minutes in accordance with official methods. However, the temperature can be reduced, if desired, and the duration of saponification can be adjusted.

No. The FLEX employs SPE (Solid Phase Extraction) as the extraction method, therefore eliminating emulsions.

Possible Causes: (1) The level sensor has failed to detect the liquid that is in the vessel. If the vessel is full and this fault screen appears, press <STOP> to drain the fluid. You may want to capture the solution and re-use it. Refer to DELTA...

While the expectation is that vitamin K is an assay that can be run on the FLEX, the method has not been validated at this time. The FLEX is a versatile instrument with many potential applications.

Yes. The extraction process, and method, are the same as the fat-soluble vitamin extraction.

This fault indicates a System Integrity Failure. One or more vessels did not reach or hold pressure properly. To resolve an MF1 fault: 1. Confirm the Low N2 setting is: 2.6 - 3.0 PSI. See Section 6.7.2 of the FLEX Operator’s Manual. 2. Tighten the...

Maintenance is low. At the end of the day, the digestion vessel spray nozzles, digestion vessel bases, and SPE column top rings must be wiped clean with a dampened towel. Some O-rings require replacement generally after about two hundred runs. Refer...

The current software will not allow for remote monitoring. This functionality may be added in future software versions.

Yes. The flow path consists solely of chemically inert materials.