Instruments

Product Categories

Resources

Possible Causes: Faulty DELTA Temp Controller ( Part #: A11 ). Refer to DELTA Service Procedure Controller Temp Test (DES014). Faulty Splat Controller ( Part #: A09 ). Poor connection between the DELTA Temp Controller and the Splat Controller.

Due to the discontinuation of certain parts, ANKOM can no longer replace the RF programmed chip (Part #: RF45) and the Circuit Board (Part #: 7007) in Gen2 modules. All other repairs and replacement parts will continue to be available indefinitely.

The ANKOM fiber instruments can analyze for either Acid Detergent Fiber (ADF), Neutral Detergent Fiber (NDF), or Crude Fiber. NDF consists of hemicellulose, cellulose, and lignin. ADF consists of cellulose and lignin. Acid Detergent Lignin (ADL)...

Protein determination is performed post the ANKOM TDF Dietary Fiber Analyzer. AOAC methods 991.43, 985.29, and 2001.03 suggest that the Kjeldahl method be used for determining protein content of the residue. AOAC methods 2009.01, 2011.25, 2017.16...

It is important that the rinse water going into the instrument is at least 50°C for Crude Fiber and 70°C for detergent fibers. For safety purposes, most hot water heaters are set lower than 70°C. In addition, if there is a substantial distance...

"The challenge was to increase analytical volume and decrease technician intervention in a controlled system that would maintain Eurofins’ standards for precision and accuracy; the ANKOM 2000 Fiber Analyzer met that goal." -Kent Karsjens, Eurofins...

"My experience with ANKOM products in past jobs in both the industrial and academic setting made the decision to purchase new ANKOM systems for the university very easy." -Professor David Vagnoni The Animal Production and Protection Department at...

There is a leak. The most common cause is a leaky Q1 valve, which would cause cooling water to flow into the vessel during the heating stage. To test: Turn the instrument completely off but keep the water supply on. Check to see if water is running...

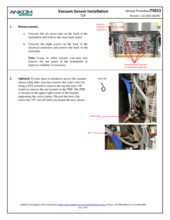

This fault display means the level sensor is indicating a full vessel when the vessel is actually empty. The level sensor has three parts: Glass Tip (visible inside the vessel) SICK Module (blue, found inside the electrical cabinet) Fiber Optic Cable...

There should not be any significant amount of solvent in the vent flask. If the solvent is dripping into the flask during the extraction, there may be a leak in valve Q7, and it may need to be cleaned or replaced. Refer to XT Service Procedure...

Possible Causes: (1) The dial on the heat sealer may not be turned up high enough. To seal the XT4 Bag, the dial must be set at approximately "6." (2) The heating element is broken. On the sides of the Teflon cover are two shiny metal strips that...

A drain error usually occurs if the level sensor is sensing solution in the vessel after the drain has opened. If the vessel is empty, and the level sensor indicates "Full," then the level sensor must be fixed. If the vessel is full of solution after...

Refer to the Fat Extraction Process section of the XT15 Extractor Operator's Manual. Review the subsection titled Sample Preparation Procedure for Crude Fat.

Just prior to use, charge your rechargeable batteries (Part #: RF16 or RF46 ) for at least three hours using the 10-Station Battery Charger ( Part #: RF25 ). A fully charged battery when plugged into a module should read 6.7V or higher on the GPM...

No, the batteries (Part #: RF16 or RF46 ) should not get hot. If this happens, the battery pack may be defective, or the module's circuit board may have failed. Install another fully charged battery pack in the module. Then, perform the module...

Possible Causes: (1) The bag suspender is worn or not properly functioning. Refer to Service Procedure Bag Suspender Check (DES006). (2) The vessel is overfilled with solution. (3) The level sensor is not detecting the solution. To service the blue...

You must run GPM software version 9.7 or greater when operating modules with temperature sensors.

The auto-graphing capability provides the user with a visual indication of the data being recorded during a gas study. However, the graphs themselves are NOT automatically stored after the study is complete. There are three ways to save the graphs...

Yes, the Dual Lead Rechargeable Battery ( Part #: RF46 ) allows you to connect the battery to both the module and the charger while the module is in use. Place the dual lead battery in the module and connect one lead to the module and the other to...

Possible Causes: (1) The dial on the heat sealer may not be turned up high enough. To seal the XT4 Bag, the dial must be set at approximately "6." (2) The heating element is broken. On the sides of the Teflon cover are two shiny metal strips that...

Possible Causes: Motor wires are loose or disconnected. Unplug the instrument. Inspect the wiring to the motor. Contact ANKOM Technology if a loose or disconnected wire is found. If the wires are intact, run this test: Turn the instrument on and...

For XT10, see Service Procedure Fault ETS (X0S002). For XT15, see Service Procedure Fault ETS (X5S016).

Possible Causes: (1) The dial on the heat sealer may not be turned up high enough. To seal the XT4 Bag, the dial must be set at approximately "6." (2) The heating element is broken. On the sides of the Teflon cover are two shiny metal strips that...

The red septa can be used repeatedly during a study as it reseals when the needle is withdrawn. When pierced during gas sampling, it is important to use a 26 gauge GC needle or smaller and avoid puncturing the membrane in the same location. The red...